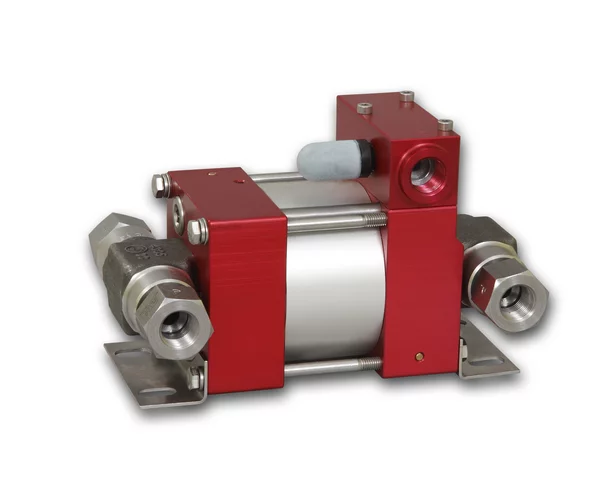

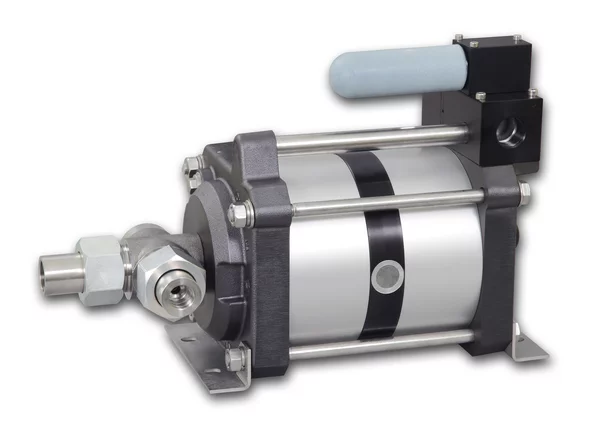

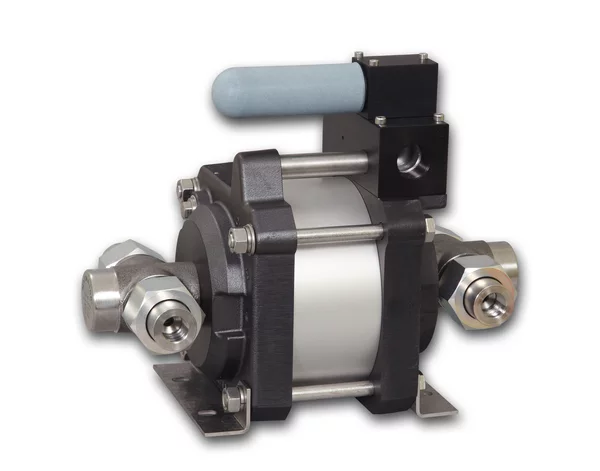

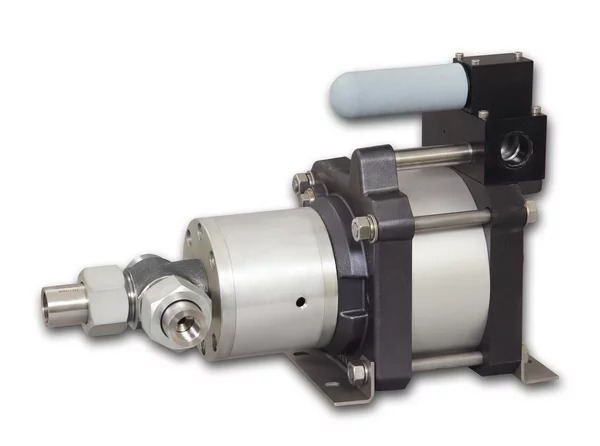

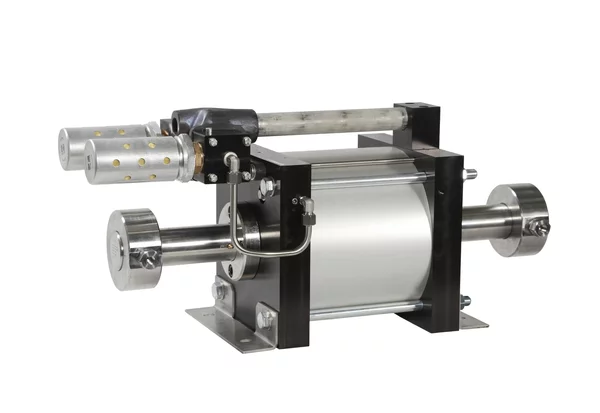

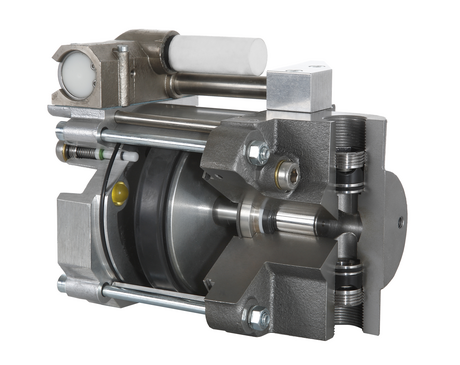

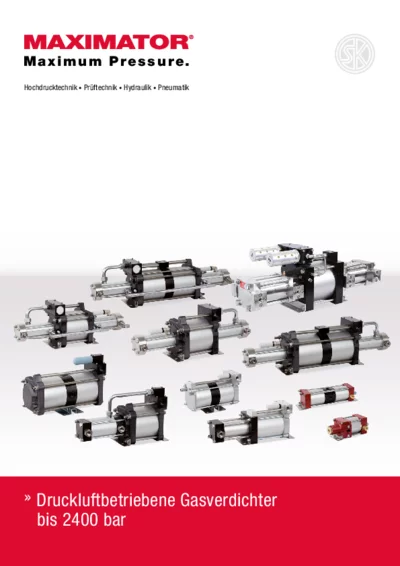

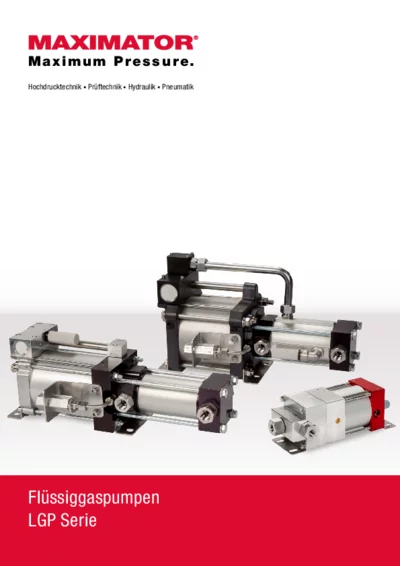

MAXIMATOR high-pressure pump is an ideal solution for generating high pressure using oil or water for various technical applications. MAXIMATOR pumps are driven by compressed air at pressures ranging from 1 to 10 bar. Generally, the design principle to the principle of an oscillating pressure multiplier which is redirected to the end positions (suction/pressure stroke) using an impulse 4/2-way valve. The gear ratio of MAXIMATOR pumps, which is simultaneously used for setting the appropriate operating pressure, results from the area of the large air piston and the small high-pressure piston. High operating pressures result from a large gear ratio.

The type marking of MAXIMATOR pumps basically reflects this gear ratio. For exact information, see Technical Data of the specific pump. The operating pressure can be easily preset with simple compressed air regulation in the air pipe. The operating pressure can be calculated by multiplying the propulsion pressure and the gear ratio of the pump. MAXIMATOR pumps perform self-priming.

Generally, a compressed air lubricator is not necessary. Due to the upward movement of the propulsion piston, the pumped medium reaches the suction side of the pump. The inlet valve opens and the outlet valve closes. During the return stroke, pressure is created on the pressure side. The inlet valve is closed and the outlet valve is open. When the pressure drops, MAXIMATOR hydraulic pumps automatically restart until the pressure is equalized.

After reaching the end pressure, which can be set using the pressure regulating valve, the pumps´ stroke frequency is reduced until they come to a complete stop while equalizing the forces between the driving and high-pressure sides. As long as the pressure does not drop on the high-pressure side, the pressure is maintained steady without energy consumption.

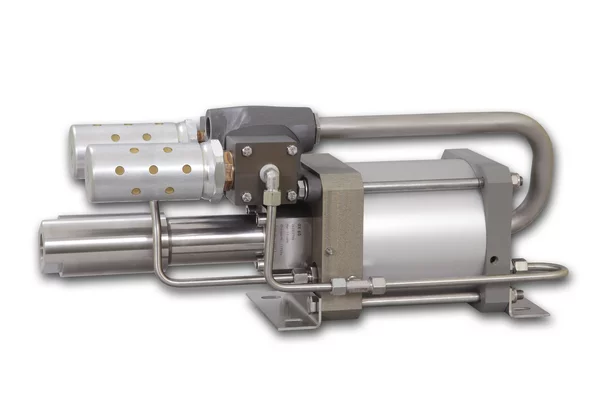

The performance of the pumps may decline due to various influences, such as freezing of the silencer or pilot valve, which is caused by high humidity of the air in the pressure pipe, choking of the air connection or contamination of the filter. Make sure to prevent reduction of the specified nominal values to ensure optimal operation of the pump.

If you have any questions about the pump´s operating conditions, please contact MAXIMATOR. We provide you with comprehensive technical consulting and competent services.

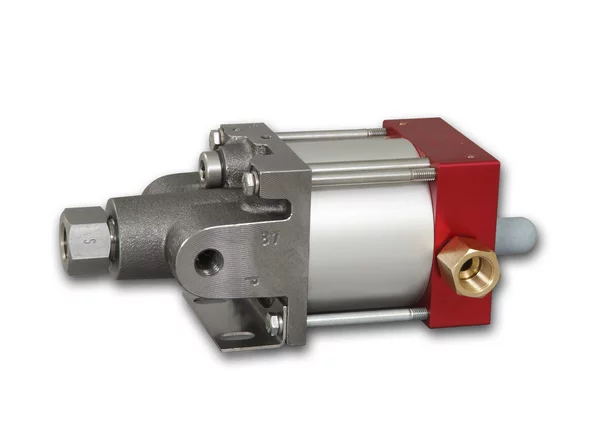

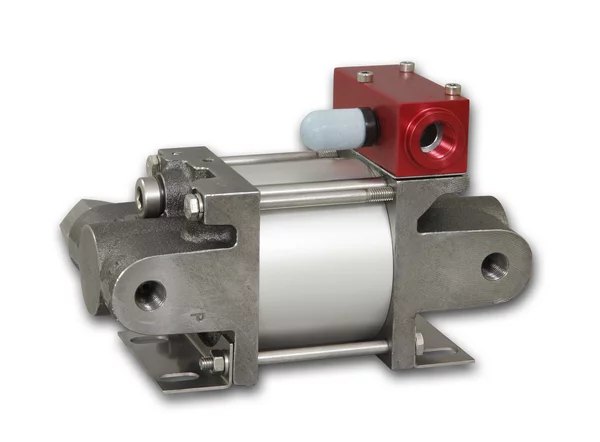

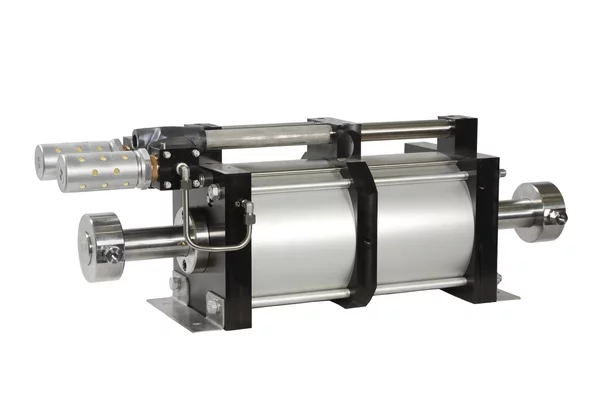

In cases of 1/2 or even 1/3 of pneumatic pressure, single-action pumps with two or three pneumatic pistons reach the same end pressures as a single-action pumps with one pneumatic piston.

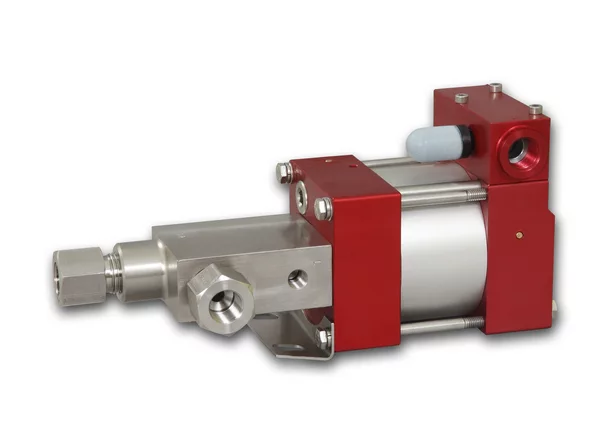

Using dual-action pumps may increase the flow rate by approx. 50 % compared to single-action pumps.