Assisted injection of plastics with gas and water

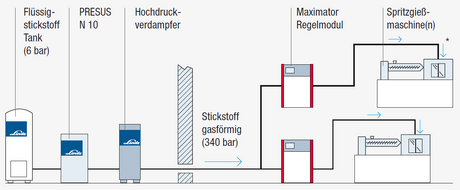

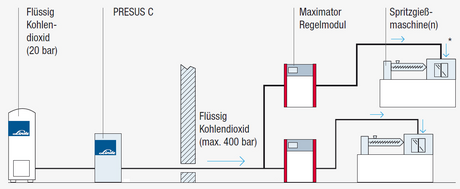

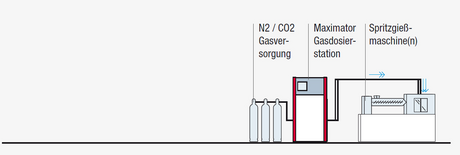

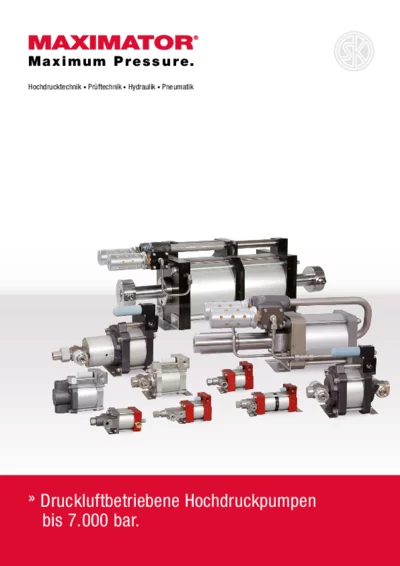

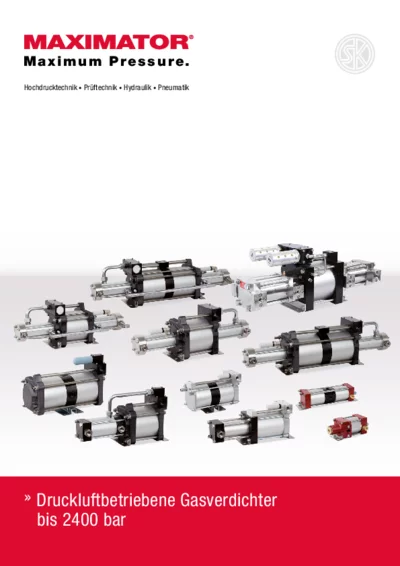

Compressor stations

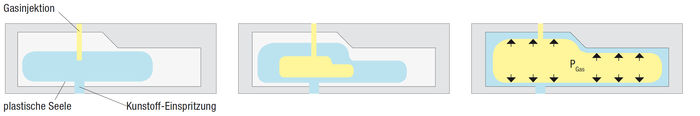

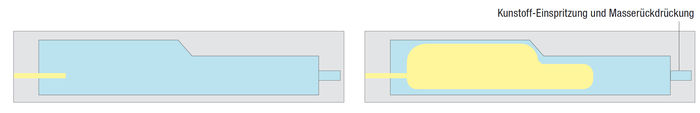

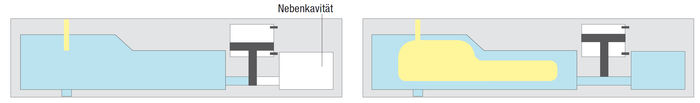

Maximator compressor stations are specially designed for pressurizing nitrogen or carbon dioxide from gas bottles and are used for generating pressure during the gas injection process.

Regulation modules

Maximator regulation modules are suitable for series production involving high-pressure nitrogen or high-pressure carbon dioxide under a pressure of 500 bar (7,250 psi). The regulation module controls the injection pressure in the GID process.

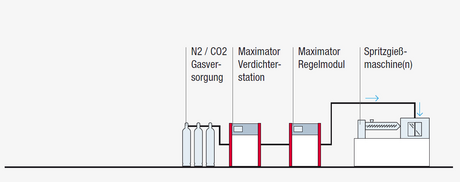

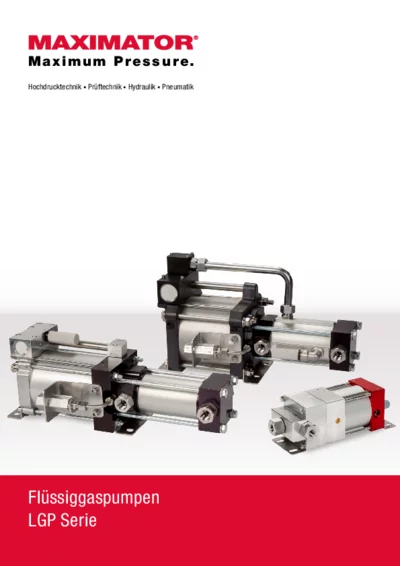

Compressor regulation modules

Maximator compressor regulation modules are used in the GIT process in the process of using mould samples or in smaller production operations using gas from gas bottles. Using the integrated Maximator compressor, gas is compressed to the required pressure and then its pressure is adjusted to the required value using the pressure regulator.

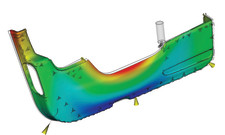

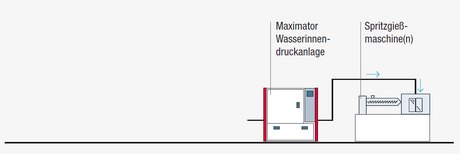

Equipment for injecting plastics with gas support

MAXIMATOR devices for injecting plastics with gas support are suitable for the WIT process in series production of components of large diameters or with channels. This variant of the injection process is characterized by significantly shorter cycle times and zero gas costs.

Gas dosing systems

MAXIMATOR gas dosing stations are designed for high-pressure dosing of inert propellant gases during physical foaming of plastics. Physical foaming of plastics is part of special technological processing, such as extrusion foaming, polyurethane foaming, and injection foaming (microcellular foaming).