Modular system for hydrogen compression

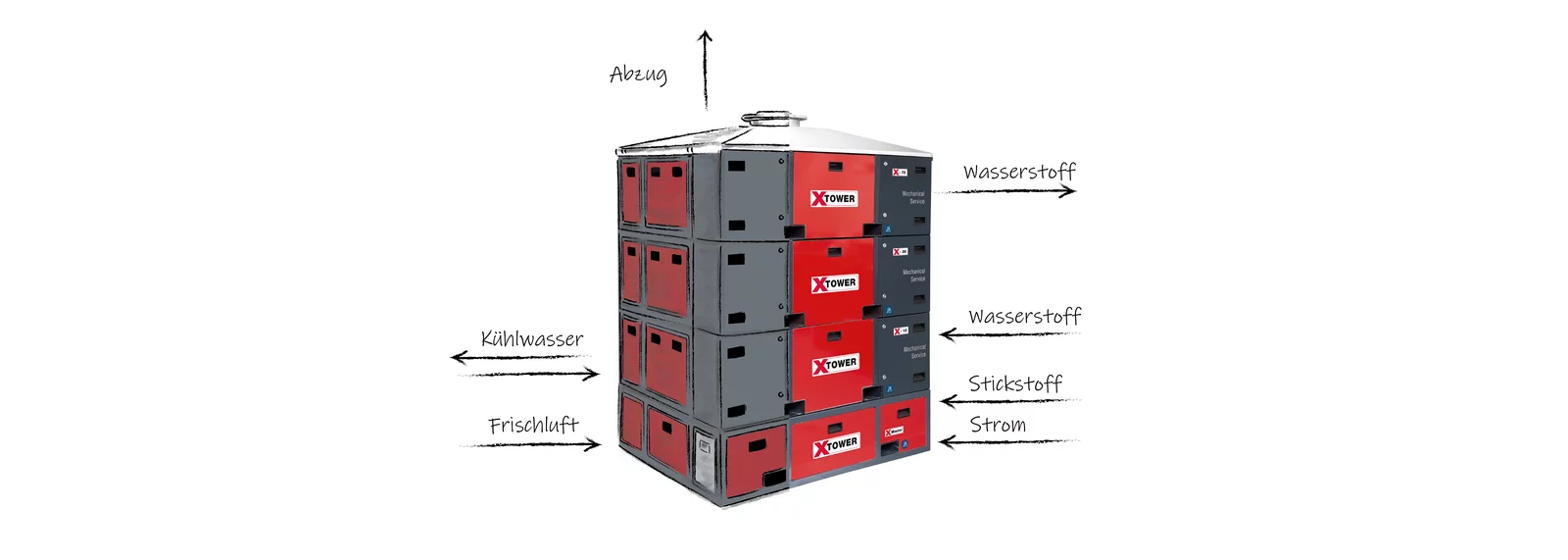

Standard configuration enabling compression of up to 900 bar consists of a MASTER module (control module) and other up to three X modules (pressure booster modules) – 1st level up to 300 bar, 2nd level up to 600 bar, and final level up to 900 bar. Through this configuration, an output gas flow corresponding to 10 kg of hydrogen per hour can be reached. In order to achieve a higher output gas flow, additional modules can be connected without problems.

Gas compression is achieved thanks to our new model series EHB (ElectroHydraulic-Booster) and this completely new electrohydraulic drive concept brings unprecedented efficiency.

For all applications, the MASTER module is a mandatory equipment; it monitors the safety and functionality characteristics of up to three other X modules. Depending on the specific application, the X modules can be combined or interconnected.