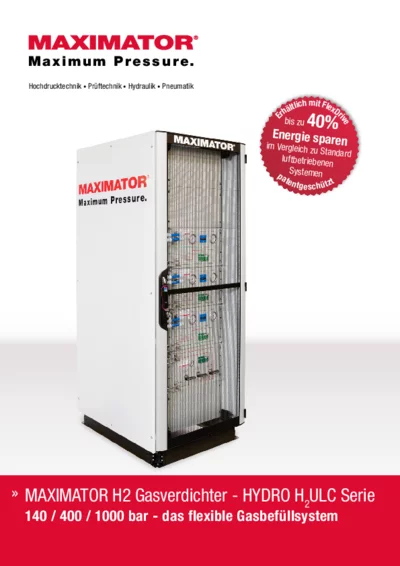

Modular system for hydrogen compression

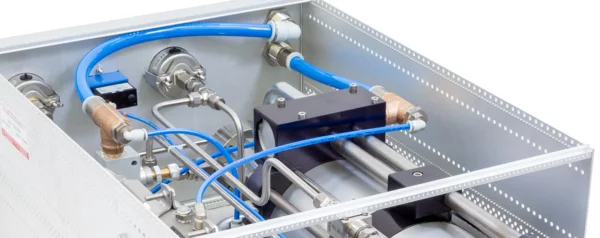

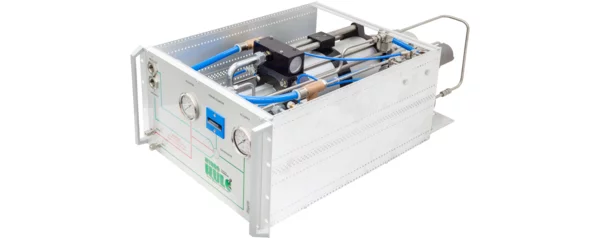

Standard configuration enabling compression of up to 1000 bar consists of a MASTER module (control module) and other up to three X modules (pressure booster modules) – 1st level up to 140 bar, 2nd level up to 400 bar, and final level up to 1000 bar. Thanks to this configuration, a mass flow rate of 2.5 kg of hydrogen per hour is created. In order to achieve higher capacities, additional modules can be easily connected.

This complete set of module sis installed in a 19“ rack frame with a mounted faceplate and front connection for easy installation, replacement, as well as access. Installing and combining modules within the system is very easy.

For all applications, the MASTER module is mandatory and it monitors the safety and functionality characteristics of up to three other X modules. Depending on the specific application, the X modules can be combined or interconnected.