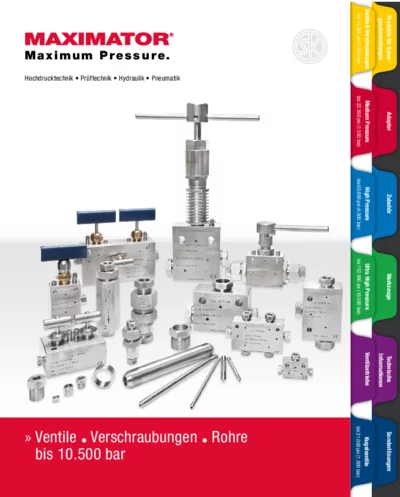

Valves, fittings and tubing

Valves 1,550 bar

- The body of MAXIMATOR valves, 21V series, is made of cold-formed stainless steel. The valve bodies are offered in six variants and can be equipped with a regulating spindle.

- In particular, the non-rotating spindle should n highlighted, as it guarantees a long service life and therefore high reliability of the valve.

Fittings 1,550 bar

MAXIMATOR fittings and threaded parts of the product line of 1,550 bar are designed for easy and reliable connection to high-pressure pipes up to a maximum pressure of 1,550 bar.

Filters 1,550 bar

- MAXIMATOR double-disc filters of the product line of 1,550 bar filter solids from gases and liquids up to a max. pressure of 1,500 bar.

- MAXIMATOR cap filters of the product line of 1,550 bar filter solids from gases and liquids up to a max. pressure of 1,550 bar.

Non-return (check) valves 1,550 bar

- MAXIMATOR non-return ball valves have a long service life and are dimensioned even for high temperatures.

- MAXIMATOR check valves with an O-ring are characterized by a leak-proof sealing. O-rings are available in all common materials for various media and operating temperatures.

Valves 2500 bar

The bodies of MAXIMATOR valves of the 36V series are made of cold-formed stainless steel. The valve bodies are offered in six variants that can be equipped with a regulating spindle.

Valves 4500 bar

The bodies of MAXIMATOR valves of the 65V series are made of cold-formed stainless steel. The valve bodies are offered in six variants that can be equipped with a regulating spindle.

Fittings 4500 bar

MAXIMATOR fittings and threaded parts of the product line of 4500 bar are designed for easy and reliable connection to high-pressure pipes up to a maximum pressure of 4500 bar.

Filters 4500 bar

- MAXIMATOR double-disc filters of the product line of 4,500 bar filter solids from gases and liquids up to a max. pressure of 4,500 bar.

- MAXIMATOR cap filters of the product line of 4,500 bar filter solids from gases and liquids up to a max. pressure of 4,500 bar.

- MAXIMATOR angle filters of the product line of 4,500 bar filter solids from gases and liquids up to a max. pressure of 4,500 bar.

Non-return (check) valves 4500 bar

- MAXIMATOR non-return ball valves have a long service life and are dimensioned even for high temperatures.

- MAXIMATOR check valves with an O-ring are characterized by a leak-proof sealing. O-rings are available in all common materials for various media and operating temperatures.

Valves 7000 bar

The bodies of MAXIMATOR valves of the 101V series are made of cold-formed stainless steel. The valve bodies are offered in six variants that can be equipped with a regulating spindle.

Fittings 10500 bar

MAXIMATOR fittings and threaded parts of the product line of 10500 bar are designed for easy and reliable connection to high-pressure pipes up to a maximum pressure of 10500 bar.

High-pressure pipes

- MAXIMATOR pipes are manufactured according to special requirements and experience acquired in the field of high-pressure technologies.

- Seamless pipes are made of cold-drawn stainless steel. They are subject to constant monitoring and checks.

Valves and fittings with pipe threading

- The bodies of MAXIMATOR valves of the 15V series with pipe threading are made of cold-formed stainless steel.

- The valves bodies are offered in two variants and can be equipped with a regulating spindle.

- In particular, the non-rotating spindle should be high-lighted, as it guarantees a long service life and therefore high reliability of the valve.

Products for sour gas applications

- Maximator offers a complete line of high-pressure valves, fittings, pipes, check valves, tubing filters, adapters, and couplings for sour gas applications (hydrogen sulfide - H2S).

- The high-pressure valves and fittings in this design series have high-pressure connections and are shipped with a thrust ring and thrust screw, unless specified otherwise.

VFT-ToolboXX, type CTTB

- A box with a set for cutting cones& and threading

- MAXIMATOR VFT-ToolBoXX, type CTTB, is a safe and well-organized way of keeping your set for cutting cones and threading.

1-1/2" valves, fittings and pipes 1,050 bar

- MAXIMATOR 1-1/2“ valves of the 15V series with a 24M connection have a body made of cold-formed stainless steel.

- The valve bodies are offered in two variants: as throughway and angle valves.

- In particular, the non-rotating spindle should be high-lighted, as it guarantees a long service life and therefore high reliability of the valve.